LOADER

Application of Seal Technology in the Loader Industry

Sealing technology plays a vital role in ensuring the reliability, efficiency, and environmental compliance of loaders. Its key applications include:

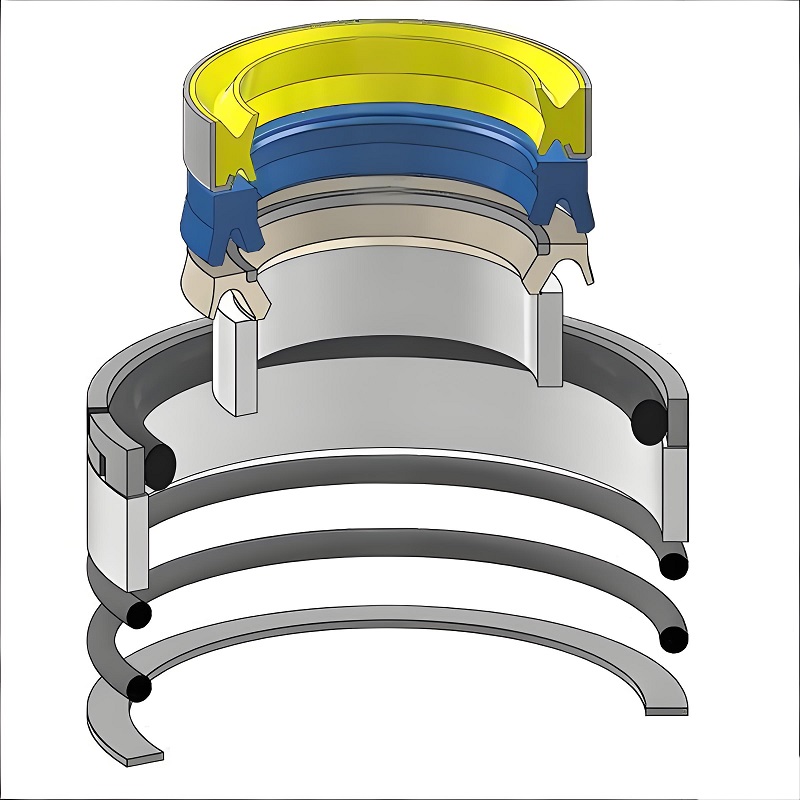

Hydraulic System Sealing: Critical components like hydraulic cylinders, pumps, and valves utilize high-performance seals (O-rings, polyurethane seals) to prevent fluid leakage, maintain stable power transmission, and reduce energy consumption and pollution.

Drivetrain and Undercarriage Sealing: Multi-layer sealing solutions (oil seals, labyrinth seals) protect transmissions, axles, and wheel hubs from contaminants like dirt and moisture, extending component lifespan and minimizing maintenance.

Engine Sealing: Components such as crankshaft seals and cylinder gaskets ensure proper oil containment and combustion chamber integrity, reducing wear and emissions while improving fuel efficiency.

Environmental and Safety Benefits: Effective sealing prevents lubricant and hydraulic fluid leaks to meet environmental standards, while avoiding equipment failures caused by seal degradation.

Advanced materials (fluororubber, PTFE) further enhance modern loader seals' durability, enabling reliable operation under extreme working conditions.