EXCAVATOR

Application of Seal in the Excavator Industry

In the excavator industry, sealing technology is critical to equipment performance, durability, and environmental protection. Its main applications include:

Hydraulic System Sealing: Excavators rely on hydraulic cylinders, pumps, and valves for power transmission. High-performance seals (such as O-rings and polyurethane seals) prevent hydraulic oil leakage, ensuring stable system pressure while reducing energy consumption and pollution.

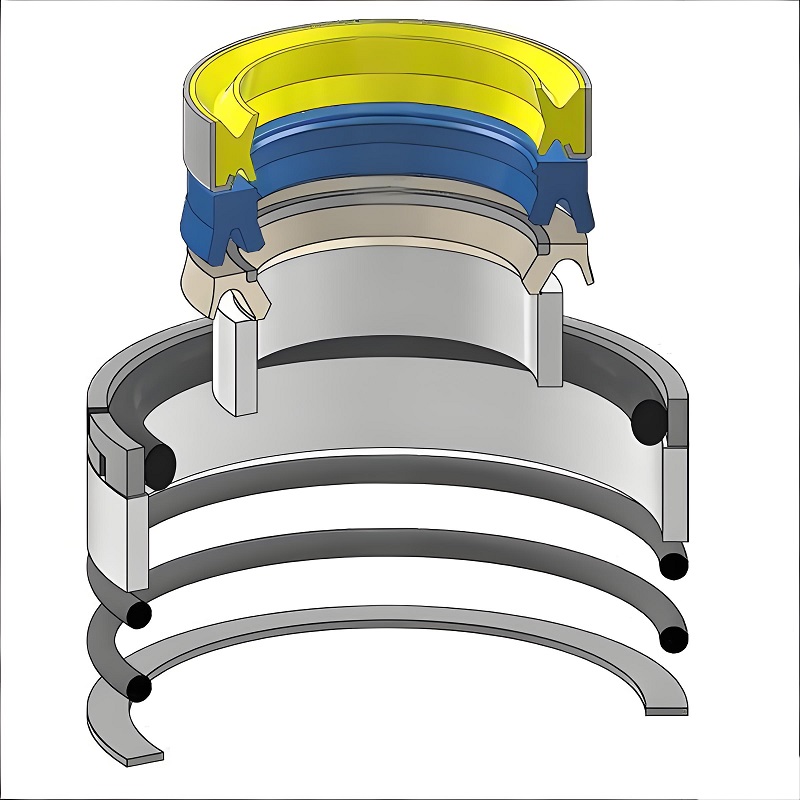

Swing Bearing and Undercarriage Sealing: Multi-layer sealing structures (e.g., labyrinth seals combined with rubber lip seals) are used in swing bearings and track rollers to block dirt and moisture, extending bearing life and lowering maintenance costs.

Engine and Transmission Sealing: Crankshaft oil seals and transmission gaskets prevent oil leakage and reduce wear, while cylinder head gaskets maintain combustion chamber airtightness, improving fuel efficiency.

Environmental and Safety Compliance: Sealing technology effectively prevents fluid leaks, meeting environmental regulations, while avoiding lubrication failure that could lead to overheating or mechanical breakdowns, ensuring operational safety.

With advancements in materials (such as high-temperature-resistant fluororubber and PTFE-coated seals), modern excavator seals offer greater adaptability, enabling reliable performance in harsh working conditions.