The O-ring (O-Ring Seal) is an elastic ring with a circular cross-section, widely used in static and dynamic sealing applications due to its simple structure, excellent sealing performance, low cost, and strong adaptability. Below are its primary uses and classifications:

Face Sealing: Used between two fixed surfaces to prevent liquid or gas leakage.

Examples: Flange connections, pipe end caps, hydraulic cylinder covers, and enclosure sealing.

Radial Sealing: Used for fixed sealing between shafts and holes (e.g., piston and cylinder fit).

Reciprocating Motion Seals:

Sealing for hydraulic/pneumatic piston rods, cylinders, and oil cylinders.

Rotary Motion Seals (under limited conditions):

Low-speed rotating shaft seals (requires lubrication to reduce friction and heat).

Oscillating Seals:

Joint sealing (e.g., robotic arms, valves).

Hydraulic & Pneumatic Systems: Sealing oil, water, or air (e.g., excavator cylinders, pneumatic valves).

Automotive Industry: Engine, transmission, fuel systems, brake systems (e.g., fuel line fittings).

Aerospace: Fuel lines, oxygen systems, and high-pressure hydraulic seals.

Medical Equipment: Infusion pumps, ventilators (sterile environment sealing).

Household Appliances: Dishwasher, washing machine hose connections.

Energy Industry: Oil pipelines, valves, and corrosion-resistant pump seals.

High/Low Temperature: Uses fluorocarbon rubber (FKM) or silicone rubber (VMQ).

Chemical Resistance: Perfluoroelastomer (FFKM) or PTFE-coated O-rings.

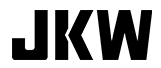

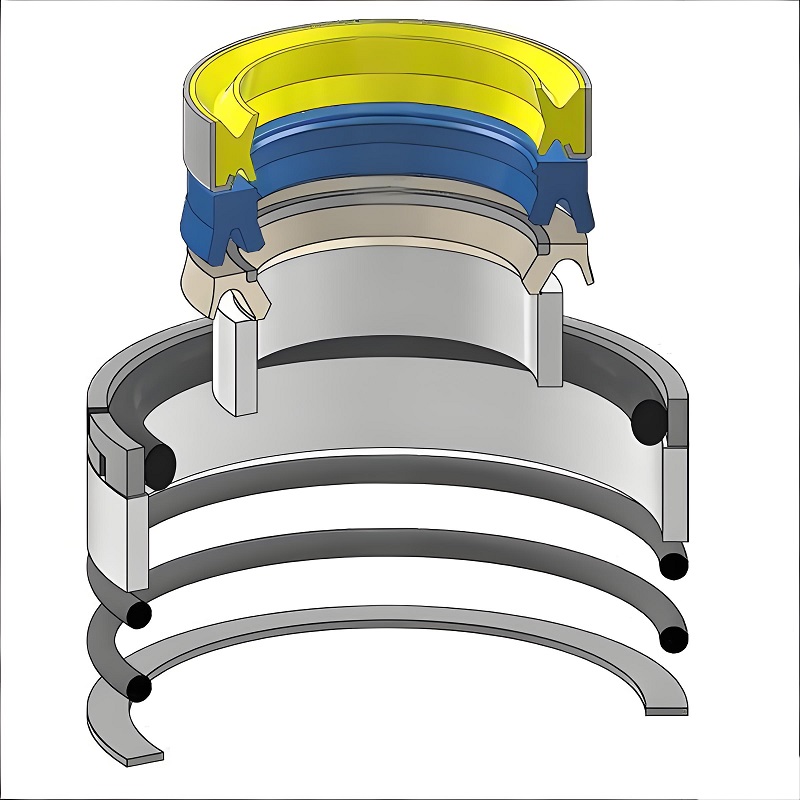

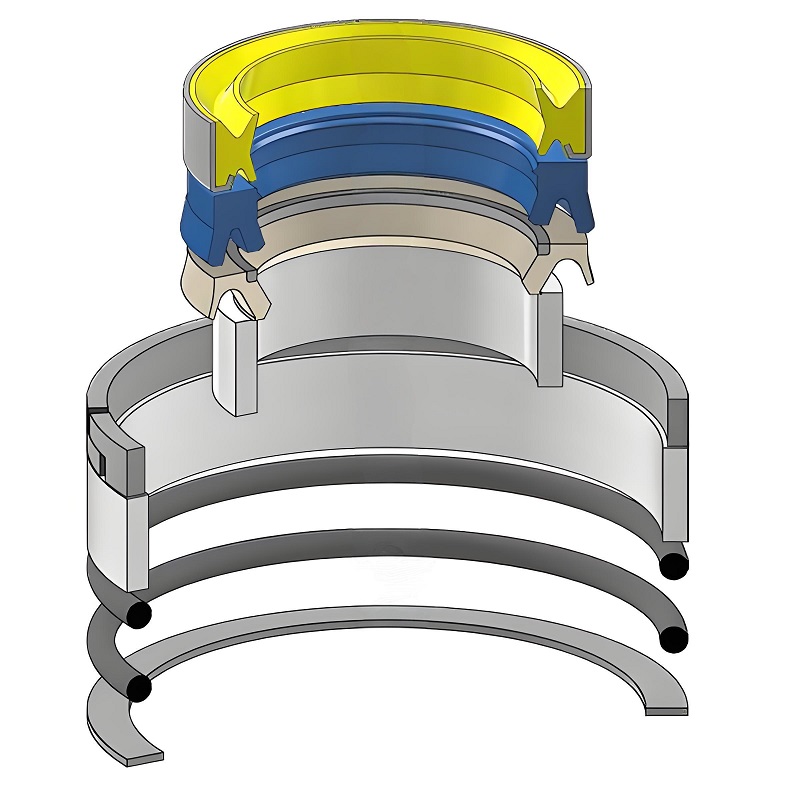

High Pressure: Requires anti-extrusion backup rings (e.g., ultra-high-pressure hydraulic seals).

Dust Seals: Prevents contaminants from entering machinery (e.g., bearing seals).

Cushioning: Absorbs vibrations in precision instruments.

Material Selection: Choose rubber/synthetic materials (NBR, EPDM, FKM, etc.) based on media (oil, acid, alkali), temperature, and pressure.

Groove Design: Sealing efficiency depends on proper groove dimensions and compression ratio (typically 10%-30%).

Dynamic Wear: High-speed or long-term reciprocating motion requires periodic replacement.

O-rings are hailed as the "king of seals" for their versatility, but extreme conditions (e.g., high-speed rotation, ultra-high pressure) may require combined sealing solutions (e.g., Step seals, Glyd rings).